Freehand Graphics™

Solutions for Screen Printers™

Save on each additional license for the same software, when purchased together!

Separation Studio® NXT

Spot Process® Sep Studio® NXT resolved your color separation struggles with raster and vector art, bad customer supplied files, and downloaded images not ready for screen printing. A stand-alone software by Freehand Graphics™ it provides industry-specific tools and production features that fit perfectly into your Adobe and Corel design world. Helping artists around the world enjoy and profit from the creative process since 1995.

AccuRIP® Emerald

AcccuRIP® Emerald software drives the entire film output process, when printing from mainstream graphics programs including Sep Studio® NXT, Adobe®, Corel® and others. Print clean, sharp, durable, high density separations to transparent film media with ease and accuracy from Epson and Canon printers. (Mac/Windows)

Separation Studio® NXT

Spot Process® Sep Studio® NXT resolved your color separation struggles with raster and vector art, bad customer supplied files, and downloaded images not ready for screen printing. A stand-alone software by Freehand Graphics™ it provides industry-specific tools and production features that fit perfectly into your Adobe and Corel design world. Helping artists around the world enjoy and profit from the creative process since 1995.

AccuRIP® Emerald

AcccuRIP® Emerald software drives the entire film output process, when printing from mainstream graphics programs including Sep Studio® NXT, Adobe®, Corel® and others. Print clean, sharp, durable, high density separations to transparent film media with ease and accuracy from Epson and Canon printers. (Mac/Windows)

Looking to Renew a License?

Buying another year of Freehand Software is as simple as the first year.

Click below to renew a 1 year license or a software bundle.

Sep Studio NXT

$229

AccuRIP Emerald

$199

NXT & Emerald Bundle

$399

Savings Club

Receive Exclusive Discounts

Starter Packages

Start Off Right

New to screen printing? With Freehand on your side you’ll be productive and profitable. Produce accurate separations and film positives quickly and easily. Make screen exposure a predictable pleasure. Start off right with a complete starter package that includes Sep Studio™ NXT, AccuRIP™ Emerald and options from Freehand’s full line of quality inkjet supplies.

Print your best.

-

Low Tack Tape (1″ x 180′)

$23.50Low-tack tape is a versatile and useful tool for screen printers operating an inkjet printer model struggling to properly read clear film media. Adding a single reusable strip of low-tack tape to the back of clear film media allows for perfect printing every time. A solution for less-than-perfect inkjet printer sensors. Includes two (2) rolls.

-

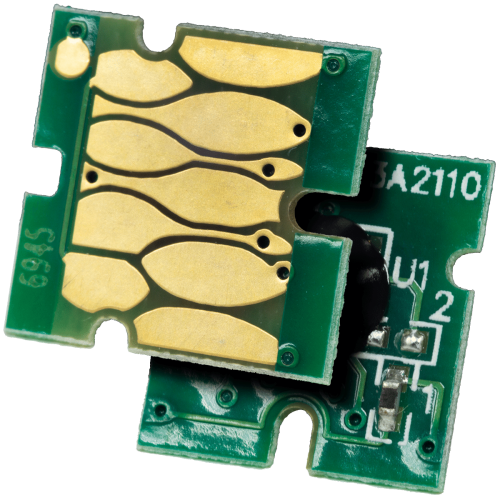

Dmax Epson T3270 Replacement Chip

$24.95Prevent downtime by having these vital 700ml refillable tank Dmax™ Epson T3270 replacement chips on hand for when you need them most. Purchase a liter of Dmax™ Black dye ink and get an Epson reset chip for FREE (limit one FREE chip per liter bottle purchase) using coupon code: RESET3270.

A dollar and a dime a day.

A bundle of AccuRIP and Sep Studio software is just $399 USD.

A bundle of AccuRIP and Sep Studio software is just $399 USD.

As a screen printer software gets you from art (start) to press production (finish). Software is an asset much like a reliable and talented creative artist, yet at a tiny fraction of the cost of any staff member or freelancer. At just $399 for a bundle that equates to spending a dollar and a dime a day to dramatically speed and control processes, manage user expectations and production costs, reduce damaging downtime, bolster your reputation, and ultimately grow your profits. Not to mention the fun you’ll have working with software engineered for the artists in an industry often ignored by software companies. At Freehand the screen print industry is its one and only focus.

When you make the bundle purchase online be sure to add an order note…write…a dollar and a dime. The sales team will email you a valuable thank you for your purchase.

The quality of your film positives is the quality of your screen prints.

Success on press relies on all aspects of the pre-press process coming together. From art file creation to color separation a lot can go wrong, slow you down and create costly downtime. That’s why the industry for four decades has trusted in Freehand, its team and the screen print focused products available right here to make printing enjoyable, reliable and profitable for even the newest shop.

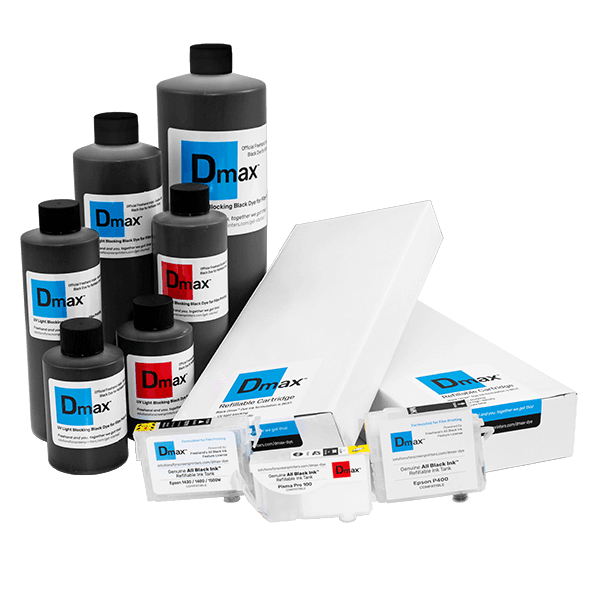

Separation Studio NXT, AccuRIP Emerald, Dmax Dye Ink in bottles and kits and DarkStar Inkjet Film is what you need for accuracy and screen exposure success. Bring these great screens to the production team and expect great press runs, outstanding prints, happy customers and profitable days.

Freehand is like no other software company serving the industry. We engineered the products to make sure screen printers don’t have to struggle to find the very best products specifically developed for pre-press. That’s why Dmax Dye Ink is more than a Freehand brand. Learn more about Dmax Inkjet Ink.

Freehand and you, together we got this!

Quality is a decision. It isn’t accidental or unachievable.

Select Freehand solutions for reliable success. Have questions on what you need? Call sales at 631-744-4330 ext 213, or email sales@solutionsforscreenprinters.com

FREEHAND IS FANATICAL ABOUT SUPPORT